News and Infos

Modernisation of the sector CNC cutting systems

2021

Investment in a CNC oxyfuel cutting system enables precise cutting quality and high contour fidelity, even with high material thickness.

Digitization of manufacturing process

2020

Conversion of operating systems to Windows 10 and a related expansion of our computer technology in all 3 production halls paves the way for paperless process control.

Expansion of production capacity

2019

In order to ensure the safe interim storage of purchased parts, semi-finished products and finished products, a new cold storage hall was built on the adjacent area off Hall 1.

2018/2019

The move to the newoffice building created more capacities for work preparation. which we were able to increase in pesonnel. Furthermore, the Former offices could be converted into the master areas. We are taking the first steps towards industry 4.0 by equipping ourselves with computer technology. The planned introduction of suitable screens and computer technology should improve the internal exchange of information in the future.

2016/2017

The acquisition of an adjacent office building enables us to expand our personnel in design and work preparation. The move to the entire office is scheduled for spring 2018. The order pre- and post-order processing, the construction and technology, as well as the manager area extend then on 2 floors.

2014

We bought 6.500 sq m commercial land for a further production hall.

2013

Through commissioning of our third production hall it is possible for us to install larger facilities completely.

2011

To cope with present and future projects we have built a new production hall of 1000 square meters. The hall is equipped with two 10-tonne gantry cranes. So we are in a position to manufacture products with a net mass as far as 20t.

Modernisation of the machinery

2018

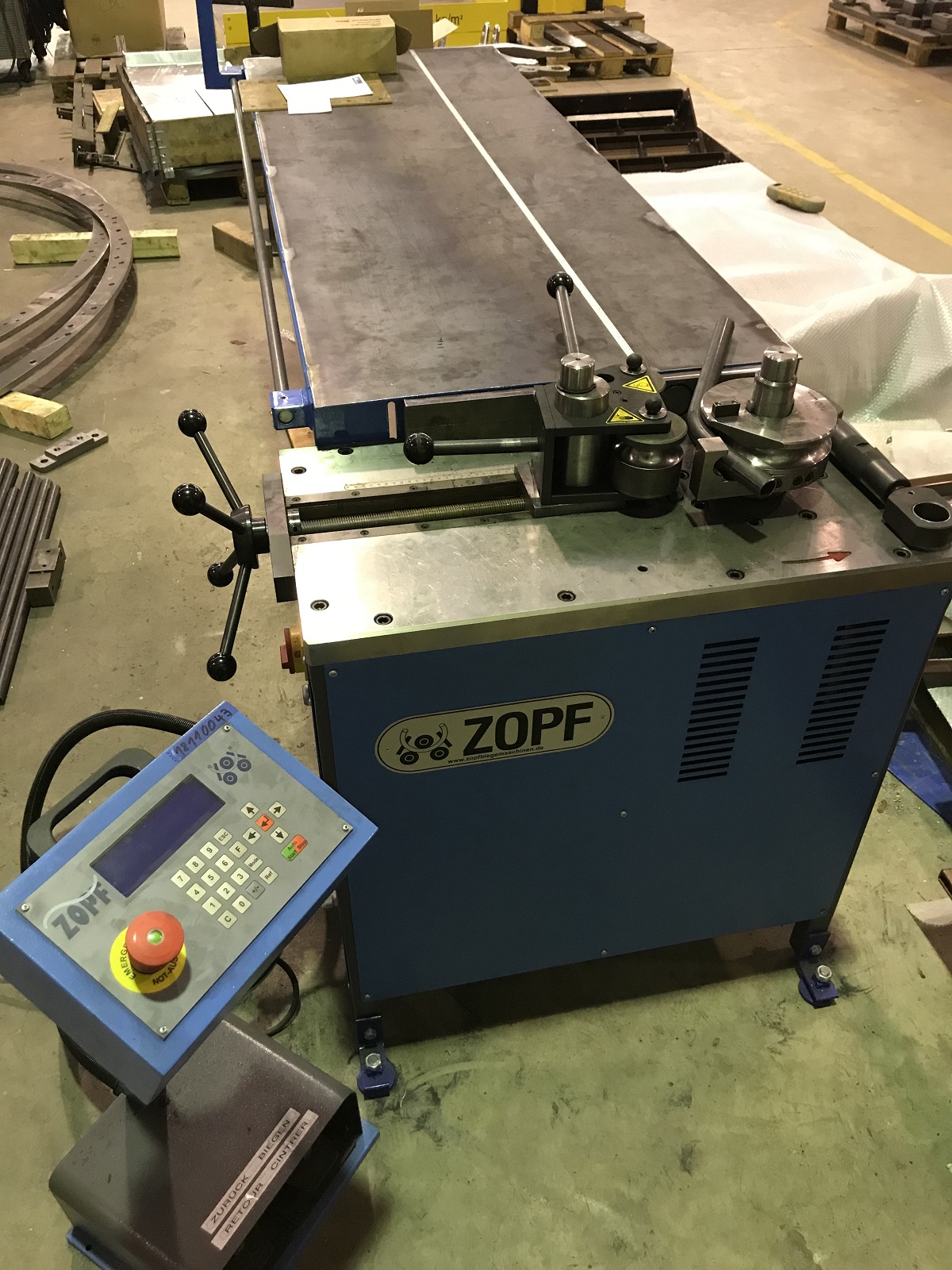

With the acquisition of a semi-automated precision bandsaw and a programmable tube bending machine, STAMA Bad Saarow GmbH was able to expand its vertical range of manufacture in metalworking.

|

|

2017

Acquisition and commissioning of a new CNC machining center type Doosan DNM 750 L II.

2016

Conversion of the tool management process of our machines through an automated, consumption-driven ordering system. The tool inventory is thereby optimized and a material bottleneck avoided.

|

|

2015

The purchase of a horizontal table boring machine WFT 13 CNC allows us to carry out the universal mechanical processing of large and heavy workpieces in our house.

- Verfahrweg x/y/z - Achse in mm 5000/2500/1500

- Tischabmessung: 2000 x 2400mm

- max. Tischbelastung 20 Tonnen

- Steuerung: Heidenhain iTNC 530

2014

We will invest 800.000 € for new equipment and machines untill 2016.

2012

A new CNC machining center type Doosan DNM 750 and a CNC lathe center type Doosan Puma 2600 LM were put into operation.

|

|

2009

We bought a new lathe with a turning diameter up to 1,100 mm and a tip length of 3,000 mm.

2008

The STAMA Stahl-und Maschinenbau GmbH get a 3-D measuring arm with a measuring range of 2.500 mm incl. the measuring software.

Additional

August 2014 / September 2017

A long-term corporate policy is also reflected, among other things, in a solid financial situation.

In addition to quality, delivery reliability and costs, the creditworthiness of a company is an increasingly important selection criterion for customer-supplier relationships.

In order to document our clients' safety in this regard, we subjected ourselves to a comprehensive balance sheet and credit check by Creditreform Frankfurt (Oder) Wolfram KG.

On August 20, 2014, we were awarded the "CrefoZert" credit rating. The recertification on September 12, 2017 confirms our continued very good credit rating with a rating of CR1.